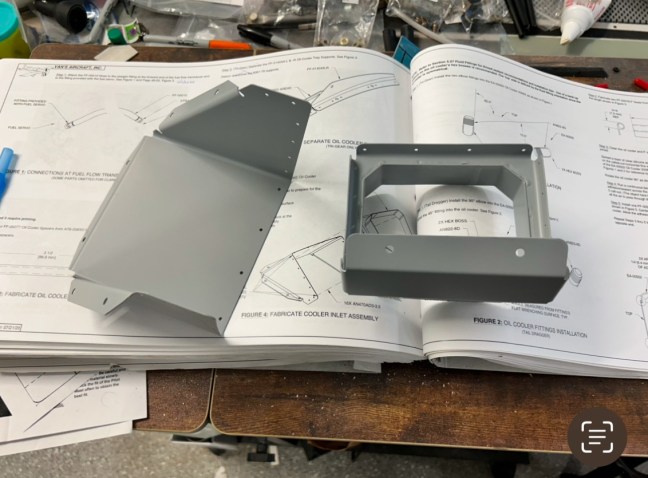

Today I worked on installing the oil cooler. I was able to get it done, but I did run into some problems. The biggest issue was that the plans called for a 60 degree clocking of one of the fluid fittings on the oil cooler. But this angle had it pointed directly at the scat tubing for the cabin heat. There was no way the oil line would have fit, and access to the fitting was limited. Unfortunately I didn’t realize this issue until I had already set the RTV and installed the air inlet. My choices were to either remove the oil cooler and the fluid fitting then reinstall at a different angle, or move the scat hose out of the way. I decided to try to move the scat hose and the related assembly to make room for the oil line. This seemed less disruptive than removing the oil cooler and redoing the RTV.

In the end I was able to move the scat hose just a little, and while it was disconnected I hooked up the oil line. Once the oil line was routed to the engine, it bent away from the scat hose just enough to make it work out.

Torquing the b-nuts on the fluid fittings was challenging, as I had to use a crow foot to apply torque. I used a wrench to hold the fluid fittings while torquing the b-nuts to avoid applying excessive torque to the oil cooler.

In the end I’m pretty happy with how it turned out.